Fmsi Auto Brake Pads Commercial Vehicles Type 0.35~0.45 Friction

Coefficient

Description of Automobile Brake Linings

| Material | Semi-metallic, Non-asbestos, Ceramics |

| Color | Black,Gray,Red,Brown,etc |

| Working Life | 80,000-100,000km |

| Certification | ISO9001, IATF16949, E-mark |

| Samples | Free |

| Samples delivery | 8-10 days |

| Delivery time | 30 days |

| MOQ | 50 sets |

| Coefficient of Friction | 0.35~0.45 |

| Package | Thermoplastic packaging +carton |

| Port | Qingdao, Shanghai, Tianjin, Guangzhou |

| Trade Term | FOB, CIF, CFR |

| Truck Brand | DAF | Daimler AG (Daimler, EvoBus Freightliner, Fuso,

Mercedes-Benz) | Dana Holding Corporation | Ege Fren | Haldex |

Hendrickson | Inver Press | Kamaz | Knorr-Bremse | Knott Group |

Krone Group (gigant) | Mack | Meritor | Paccar (DAF, Leyland,

Foden) | Schmitz Cargobull | Tuna Stålrör | Valx | Volvo Trucks

(RVI, UD Trucks, Volvo) | WABCO | Beinben-Truck | BPW | Brakes

India Limited | Wuhan Youfin Auto Parts Co (Youfin) | Yutong | ZF

Friedrichshafen |

| HS code | 87083010 |

| Application | heavy-duty truck, trailer, semi-trailer, commercial vehicle, Bus &

Truck |

BAIYUN Automobile Brake Pads & Linings

1), Automobile Brake Linings

Model List of Automobile Brake Linings

Advantage of Automobile Brake Linings

1. High quality raw materials

2. Good heat dissipation

3. Do not damage the drum

4. Low noise

5. Good friction coefficient.

6. High temperature resistant

7. Environment-friendly

8. High Perfomance

9. Reasonable price,good quality .

10. More than 1000+ specifications

11. Super wear-resistant

12. Low density, low weight

2), Automobile Brake Pads

Test Results of Automobile Brake Pads

BAIYUN Vehicle Friction Brake Pads

Powder Coat & Zinc Dichromate Coat

Superior corrosion resistance and smooth brake engagement.

Friction Material

Excellent formulations deliver superior stopping power and

durability

Surface Preparation

Diamond ground for exceptional surface conditioning and flatness.

Slotted Friction

Removal of friction debris.

Bonding Layer

Excellent adhesive and bonding material

Backing Layer

Special backing material to get thermal-protective layer

Steel Backing Plate

OED standard backing plate

Shim

Dampen noise and hot

PAD CHAMFER

Engineered to eliminate noise and vibration.

Friction Materials

Top Auto Friction Braking Enterprise Of China Automobile Brake Pads

& Linings With E11 - Zhengzhou Baiyun Industrial Co., Ltd.

Zhengzhou Baiyun Industrial Co., Ltd., since 1977, is a national

high-tech enterprise with main products of brake friction material

and its products. For more than 40 years, Baiyun focus on the

R&D, production and selling of brake linings & pads for

commercial and passenger vehicles, fighting for human traffic

braking safety. Till now, Baiyun has become an important supporting

supplier and partner of many famous domestic and overseas auto

brands. Baiyun has also reached long term strategic cooperation

with many famous domestic and overseas auto parts distributors.

Zhengzhou Baiyun Industrial Co., Ltd., is one of the leading auto

friction braking enterprise in China, Top 10 enterprises of China

Friction Material Industry and member of friction industry

association. Baiyun has passed ISO9001 Quality Management System,

IATF16949 Auto Industry Quality System Certification. Long-term

cooperation is established with international authoritative test

organizations such as America LINK and GREEN to test Baiyun

products regularly. More than 1000 models products have obtained

E-mark certification.

Baiyun will insist on the enterprise mission "create value for

customers, create happiness for employees" continuously forge

ahead, and create a more brilliant future.

About BAIYUN Top Auto Friction Braking Enterprise Of China

FAQ of BAIYUN Vehicle Brake Pads

Q1. What is your terms of packing?

A: Paper Carton or Neutral Packaging

Q2. What is your terms of payment?

A: T/T or L/C, D/A

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF,FCA, CPT, CIP, DDU.

Q4. How about your delivery time?

A: Generally, 30days

Q5. Can you produce according to the samples?

A: Yes, of course

Q6. What is your sample policy?

A: We can supply the sample for free,but the customers have to pay

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

1. We keep good quality and competitive price to ensure our

customers benefit ;

2. We respect every customer as our friend and we sincerely do

business and make friends with them,

no matter where they come from.

Vehicles Brake Linings

Drum brake is a brake that uses friction caused by a set of shoes

or pads that press outward against a rotating cylinder-shaped part

called a brake drum. Drum braking linings have brake drums that

rotate with the wheels.

Brake shoes fitted with drum brake linings (friction material)

which press against the drums from the inside to generate braking

force (decelerate and stop) are set inside of the drums.

With this system, friction is generated by pressing the brake

linings against the inside surfaces of the drums. This friction

converts kinetic energy into thermal energy. Drum rotation helps to

press the shoes and the lining against the drum with more force,

offering superior braking force in comparison with disc brakes. On

the other hand, it is very important to design the components so

that the heat from the thermal energy is dissipated efficiently

into the atmosphere.

There are three types of drum brakes depending on how the brake

shoes are pressed on to the drums; leading/trailing shoe type, twin

leading shoe type and duo-servo type.

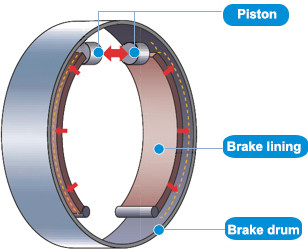

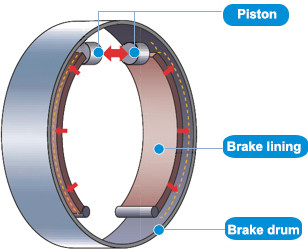

Structure of Vehicles Brake Linings

Drum brakes are a brake system with brake drums (rotor) which

rotate with the wheels. Inside each drum are brake shoes fitted

with brake linings (friction material). Pistons (pressure

mechanism) press against the drums from the inside to generate

braking force, thus making is possible to decelerate and stop the

vehicle.

How Vehicles Brake Linings work ?

When the driver steps on the brake pedal, the power is amplified by

the brake booster (servo system) and changed into hydraulic

pressure (oil-pressure) by the master cylinder. The pressure

reaches the brakes on the wheels via tubing filled with brake oil

(brake fluid). The delivered pressure pushes the pistons on the

brakes of the four wheels. The pistons press the brake linings,

which are friction materials, against the inside surfaces of the

brake drums which rotate with the wheels. The linings are pressed

on the rotating drums, which in turn decelerate the wheels, thereby

slowing down and stopping the vehicle.

Main components of drum brakes